Solbian SP (SunPower) Range Purchase Guide

Author: Solar 4 RVs

This guide provides information about Solbian's SP range and what Solar Charge Controller to use for each panel.

Solbian SP series panels are made in Italy and uses SunPower patented back-contact monocrystalline silicon cells which eliminates conductors on the top surface which reduces the efficiency of other cells in comparison. The cell efficiency of 24% enable the SP range to provide the highest output power from the smallest surface area of any panel available today and hence are recommended for installations on yachts where maximum power is required from limited surface area. The SunPower cells also achieve the lowest loss in partial shading and high temperature situations compared with other cells.

Datasheet: https://www.solbian.eu/img/cms/PDF/SP_eng.pdf

Installation Manual: http://www.solbian.eu/img/cms/PDF/Solbian_installation_manual.pdf

Features of Solbian SP range

- Most efficient flexible module on the market (highest output power from the smallest surface area)

- Flexible and lightweight (2.2 kg/m2)

- Completely waterproof and resistant to salt water

- Thin (less than 2 mm)

- 5 year warranty against manufacturing defects

- Integrated bypass diodes to minimise output losses associated with partial shading

- Available with different front sheets, many fixing and electrical wiring options (special order)

- White, black or transparent back sheet (special order)

- Junction box on top or underneath (special order)

- 316 stainless steel eyelets (fitted by Solar 4 RVs)

- Bi-adhesive backing covering the entire back surface of the panel (special order)

- Charge higher voltage 12V, 24V, 36V or 48V batteries, lead-acid or lithium from a low voltage panel using Genasun boost charge controllers

- Designed and manufactured in Italy

| SP 144 | SP 130 | SP 118 L | SP 118 Q | SP 104 | SP 78 | SP 52L | SP 52Q | |

| Maximum power [W] | 144 | 130 | 118 | 118 | 104 | 78 | 52 | 52 |

| Length Y [mm] | 1490 | 1363 | 1236 | 855 | 1109 | 855 | 1109 | 601 |

| Width X [mm] | 546 | 546 | 546 | 800 | 546 | 546 | 292 | 546 |

| Thickness [mm] | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Weight [kg] | 1.9 | 1.7 | 1.6 | 1.6 | 1.4 | 1.1 | 0.8 | 0.8 |

| Columns x Rows (cells n°) | 4x11 (44) | 4x10 (40) | 4x9 (36) | 6x6 (36) | 4x8 (32) | 4x6 (24) | 2x8 (16) | 4x4 (16) |

| Max power Voltage Vmp [V] | 25.3 | 22.8 | 20.7 | 20.7 | 18.2 | 13.7 | 9.1 | 9.1 |

| Open circuit voltage Voc [V] | 30 | 27.3 | 24.5 | 24.5 | 21.8 | 16.4 | 10.9 | 10.9 |

| Max power Current Imp [A] | 5.7 | |||||||

| Short circuit current Isc [A] | 6 | |||||||

| NOCT [°C] | 45 ± 2 | |||||||

| Operating temperature [°C] | -40 to +85 | |||||||

| Temp. coeff. Pmax [%/°C] | -0.38 | |||||||

| Temp. coeff. Voc [%/°C] | -0.27 | |||||||

| Temp. coeff. Isc [%/°C] | 0.05 | |||||||

| Maximum system voltage [V] | 1000 V | |||||||

| Maximum reverse current [A] | 12A | |||||||

| Safety class | A | |||||||

Specifications for Solbian SP Range

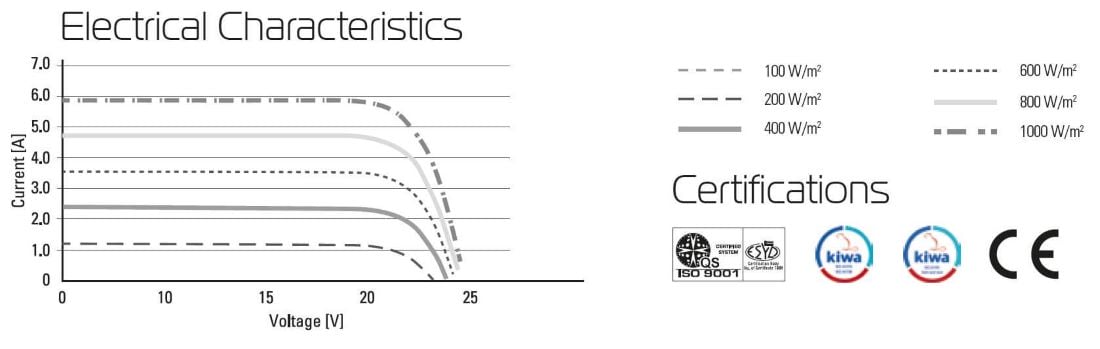

* Values at STC = Standard Test Conditions: (a) light Spectrum for an Air Mass of 1.5; (b) irradiance of 1000 W/m2 with perpendicular incidence and (c) cell temperature of 25 °C. Measurements carried out according to the Standard IEC 61215 requirements.

* This NOCT is based on the STC and assume an air gap behind with 1m/s air flow. In practice a panel directly bonded to an insulated substrate will be much hotter

** For best case safety, only wire in series to raise the string voltage high enough to use with a conventional voltage dropping MPPT charge controller, e.g 18V for a 12V battery, 36V for a 24V battery

Selecting the most appropriate Controller/Regulator

Solbian only uses whole cells. This means that the voltage increases with the panel wattage, whereas the current is the same for all panels. For example the SP52 has 16 cells in series giving just over 9V, whereas the SP104 has 36 cells in series giving just over 18V. The amps for both panels is 5.7Amp.

You will need a Genasun MPPT voltage boosting charge controller if you need to charge a battery that has a higher voltage than the panel, otherwise a Victron MPPT charge controller is recommended for boats where the panel Voltage (Vmp) is at least 50% above the battery nominal voltage*, ie, Vmp = 18V for a nominal 12V battery; Vmp = 36V for a nominal 24V battery, 72V for a 48V battery (irrespective of the battery being lead-acid or lithium. Otherwise a PWM charge controller is recommended where the Vmp is above the battery voltage but doesn't meet the required voltage for the MPPT to work.

*applies to most batteries but there are exceptions and we are happy to advise if unsure.

Recommended Controller for each Solbian SP panel and battery voltage

Always contact Solar 4 RVs in case of doubt.

Nominal Battery voltage. Genasun provides separate chargers for different chemistries, whereas the Victron chargers are suitable for both lead-acid and lithium.

| Panel | Vmp | Imp | 12V | 24V | 36V | 48V |

| SP52L | 9.1 | 5.7 | Genasun GVB-12 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP52Q | 9.1 | 5.7 | Genasun GVB-12 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP78 | 13.7 | 5.7 | Genasun GVB-12 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP104 | 18.2 | 5.7 | Victron MPPT 75/10 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP118L | 20.7 | 5.7 | Victron MPPT 75/10 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP118Q | 20.7 | 5.7 | Victron MPPT 75/10 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP130 | 22.8 | 5.7 | Victron MPPT 75/10 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

| SP144 | 25.3 | 5.7 | Victron MPPT 75/10 | Genasun GVB-24 | Genasun GVB-36 | Genasun GVB-48 |

* Alternatively, to use a conventional Victron MPPT charge controller, panels can be wired into series which increases the voltage, e.g. four SP104 panels wired in series provides 128 cells in series giving 4x 18.2V = 72.8V which can be used for charging a 48V battery system. The wattage is 4 x 104W = 416W. At 48V, the theoretical maximum amps is 416W / 48V = 8.6A. In real-life with a hot panel under a hot sun the efficiency is lower so the maximum amperage is up to 80% of the theoretical. The smallest Victron MPPT charge controller for 48V is the SmartMPPT 100/20.

Minimum number of cells in series that is required for a Victron MPPT charge controller

The following table lists the minimum number of cells in series that are required so that a conventional charge controller can be used and accommodate the voltage drop of the panel as temperature rises. For safety, it is always recommended that DC voltage is kept as low as possible, i.e. a minimum number of panels are wired in series, i.e only wire enough panels in series just sufficient to provide the necessary Vmp required by the MPPT charge controller. For example, Victron requires a Vmp of at least 4V above the battery voltage when the panel is hot.

| 12V | 24V | 36V | 48V | |||

| SunPower SP range | 32 | 64 | 96 | 128 | ||

| SR & SX Range | 36 | 72 | 108 | 144 | ||