Contactor 500A 1000VDC NO, Coil 48-72VDC w/ Economiser

Contactor 500A 1000VDC NO, Coil 48-72VDC w/ Economiser

Hermetically sealed arc chamber, aux contact, low-hold economiser

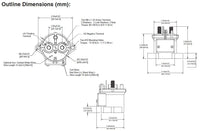

Highlights:M8 Screw Terminals: High current threaded terminals for secure electrical connection,Polarity Barrier: Integrated insulator between terminals to prevent arcing,Technical Specifications: Printed specifications including 48-72VDC coil rating,Mounting Flange: Durable base with dual mounting holes for secure installation.

Highlights:M8 Screw Terminals: High current threaded terminals for secure electrical connection,Polarity Barrier: Integrated insulator between terminals to prevent arcing,Technical Specifications: Printed specifications including 48-72VDC coil rating,Mounting Flange: Durable base with dual mounting holes for secure installation. Key features: M8 x 1.25 screw terminals with 8.8-11 Nm torque rating, Dual #10 mounting holes with 1.7-3.3 Nm torque rating, 80.7mm total width and 72.6mm total height, 390mm standard coil wire length.

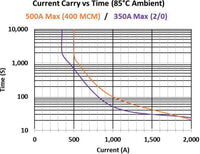

Key features: M8 x 1.25 screw terminals with 8.8-11 Nm torque rating, Dual #10 mounting holes with 1.7-3.3 Nm torque rating, 80.7mm total width and 72.6mm total height, 390mm standard coil wire length. Performance graph illustrating current carry capacity over time at 85°C ambient temperature for 400 MCM and 2/0 cable sizes, demonstrating thermal handling capabilities up to 2000A.

Performance graph illustrating current carry capacity over time at 85°C ambient temperature for 400 MCM and 2/0 cable sizes, demonstrating thermal handling capabilities up to 2000A.

DESCRIPTION

High-Voltage DC Switching for EV, ESS and Solar Power Systems

This hermetically sealed 500A DC contactor is designed for demanding high-voltage applications where controlled switching, reduced arcing risk and long-term reliability matter. With a normally open (SPST-NO / 1 Form A) main contact arrangement, it helps keep your circuit isolated until the control coil is energised—an important safety and system-design advantage in EV powertrains, battery energy storage systems (BESS), PV combiner/battery disconnect functions and industrial DC power control.

For Australian installers and OEMs working with high-voltage DC architectures, this unit supports cleaner integration into 48–72V control systems thanks to a built-in coil economiser. By reducing holding current once the contactor is closed, the economiser can help lower steady-state power draw and heat generation in control enclosures—particularly valuable in tightly packed EV conversions, mobile power setups and ESS cabinets.

Designed to Reduce Common HVDC Switching Issues

High-voltage DC switching places unique stress on contactors, especially with capacitive loads (inverters, DC-link capacitors) and inductive sources (alternators, motors). This contactor uses an inert gas-filled arc chamber and a hermetically sealed design to support stable switching performance and reduce the likelihood of arc leakage into the surrounding environment.

Because contact surfaces naturally wear with each operation, system-level practices can extend service life and reduce electrical stress: pre-charging high-capacitance loads before closing main contacts helps reduce closure wear, and discharging inductive circuits prior to opening—along with appropriate flyback/avalanche diode strategies—helps manage stored energy paths.

Key Features

- 500A continuous current capability for high-demand DC buses and battery systems

- Up to 1000VDC switching platform suited to modern HV architectures in EV and ESS

- Normally open (SPST-NO / 1 Form A) design to keep circuits isolated until commanded

- Built-in coil economiser to minimise holding current and reduce control power consumption

- Hermetically sealed construction to support reliability and help prevent arc leakage

- Compact, low-profile, low-noise operation for easier packaging in cabinets and vehicle builds

- Auxiliary contact included for status signalling, interlocks or controller feedback

Where It Fits Best

This DC contactor is commonly used as a battery disconnect contactor, main HV enable/disable device, or controlled switching element in systems such as:

- EV conversions and EV auxiliaries where robust DC isolation and control integration are required

- Battery energy storage systems (ESS/BESS) for DC bus switching and protection schemes

- Solar + storage and DC-coupled PV applications needing high-voltage DC control

- Industrial DC power for power control, circuit protection architectures and remote isolation

Compliance and Build Confidence

The contactor is specified to meet RoHS requirements and is CE certified (UL pending). Its ability to be mounted in any orientation provides flexibility for enclosure layout and cable routing—helping simplify mechanical design without compromising intended performance.

Integration Notes for Reliable Results

For best outcomes in high-voltage DC systems, ensure your design includes appropriate pre-charge/discharge methods and protective components suited to your load type. Correct conductor sizing, termination quality and thermal management are also critical for high-current applications.

See attached datasheet for detailed electrical and mechanical information.

SPECIFICATIONS

Coil actuator specification (has built-in economiser to minimise holding current)

- Voltage (Will Operate) 32-95VDC (Valid Over Temperature Range)

- Voltage (Max.) 95VDC

- Pickup (Close) Voltage Max. 32VDC

- Hold Voltage (Min.) 22VDC

- Dropout (Open) Voltage (Min.) 18VDC

- Inrush Current (Max.) 1.3A

- Holding Current (Avg.) 0.03A@48V

- No back EMF

| SKU: | AM-AEV250-GAN |

| Barcode: | |

| Model #: | AEV250-GAN |

| MPN: | AEV250-GAN |